FACILITIES

EQUIPMENT LIST

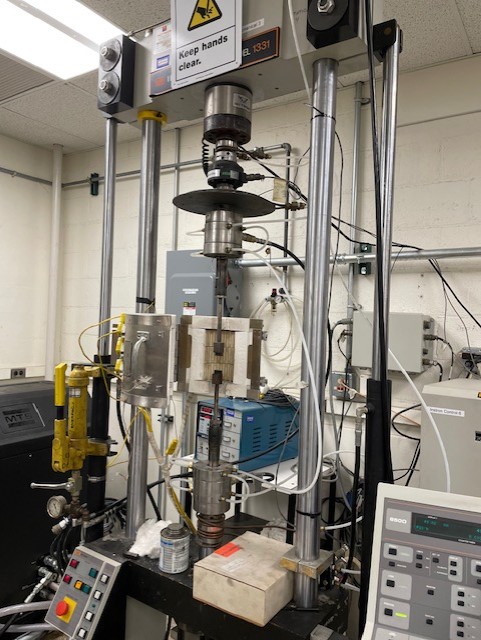

AMTEL provides access to a wide range of test machines and equipment to investigate material behavior. The lab includes test frames with a range of tension-tension and tension-torsion loading at rates appropriate for creep testing up to high cycle fatigue analysis. Each of these machines can additionally be coupled with a broad range of temperature control capabilities.

Machine capacities vary from 10 N to 400 kN for sample dimensions ranging from microns to centimeters. In conjuction with these servohydraulic and screw driven load frames, AMTEL has developed a state-of-the-art optical stress analysis lab with modern tools for Digital Image Correlation (DIC), Photoelastic Stress Analysis (PSA), Thermoelastic Stress Analysis (TSA) as well as Thermography capabilities for nondestructive testing. Metallic, polymer, semiconductor, biological, ceramic, and composite samples can be tested to study the fatigue, creep and fracture behavior of materials and components.

LOAD Frames

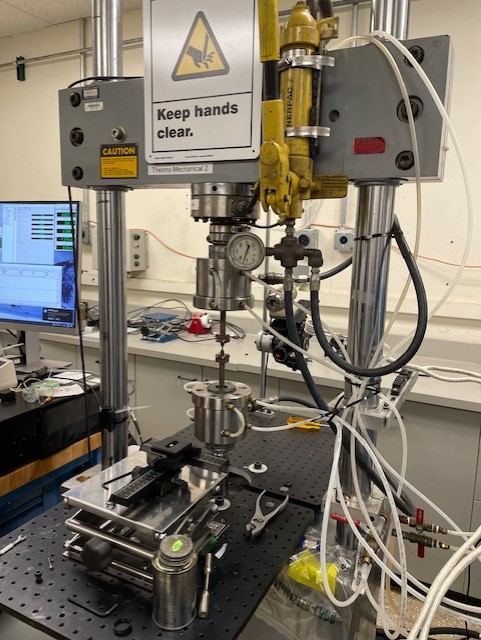

Psylotech’s μTS is specifically designed to keep a sample in- plane during testing. The result is a sophisticated instrument well suited for:

• Continuum Model Validation of finite element analysis through multi-scale testing

• Miniature Sample Testing to facilitate material development where quantities can be low

• Unprecedented Versatility to enable implementation of new experimental techniques

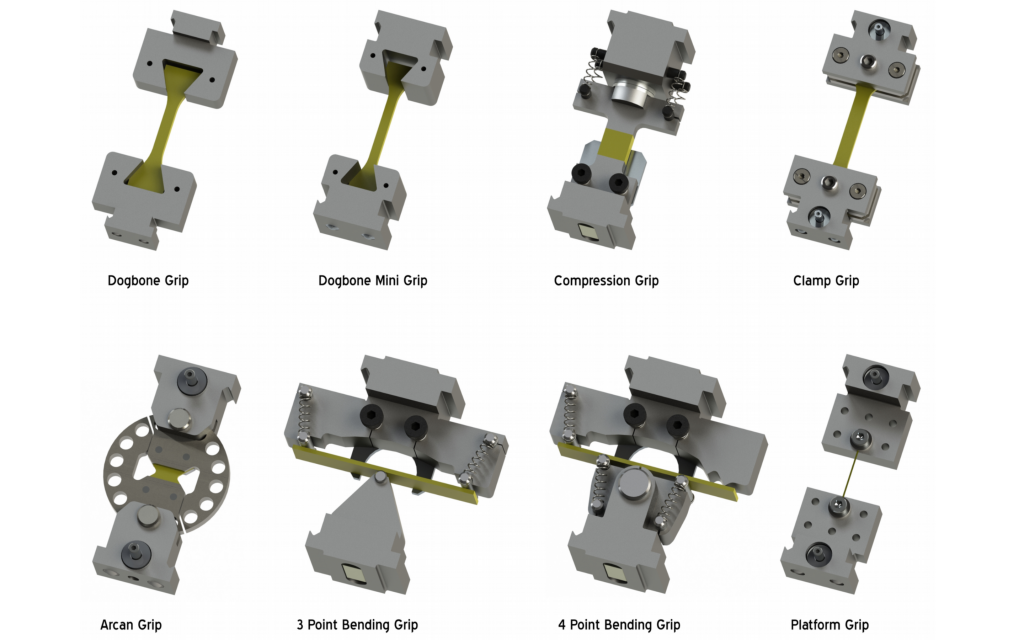

Psylotech’s μTS includes a wide range of features which separate it from any other under-microscope system currently on the market today. These features allow for new possibilities in material testing applications in addition to novel experimental techniques. Such as -Large Grip Variety

Aluminum bar max speed: 60 ft/s

Steel Bar max speed: 100 ft/s

Incident/Transmission Bar Diameter: 0.75 in

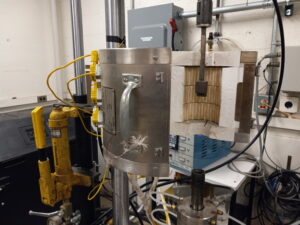

Thermal Loading

ATS 3210

Max Temp: 2000°F

ATS 3710

Max Temp: 800°F

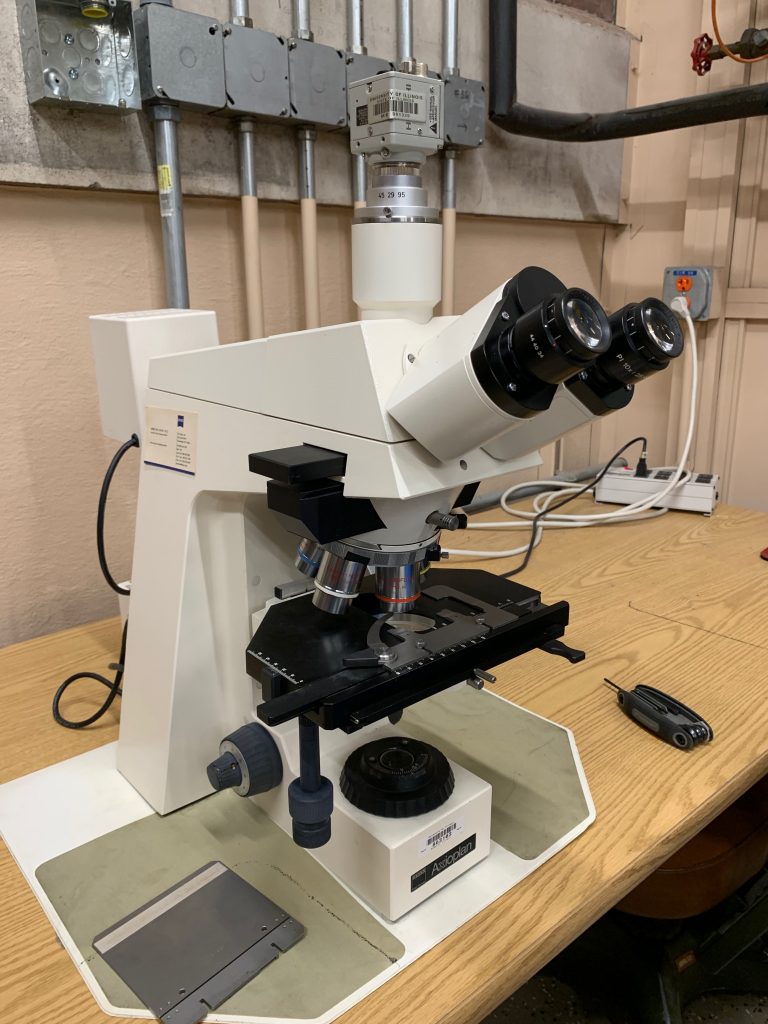

Diagnostic Equipment

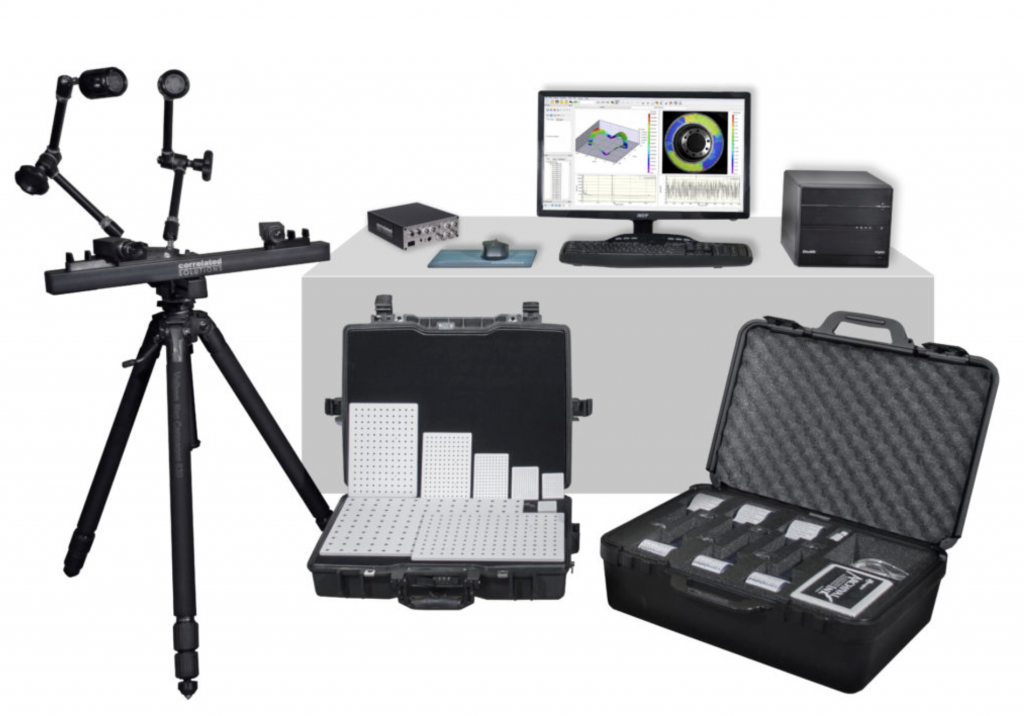

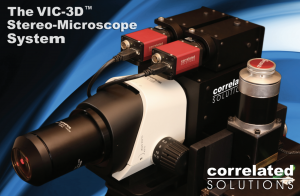

Measures and visualizes full-field, 3-Dimensional measurements of shape, displacement, and strain on a surface

Measures displacements down to nanometer resolution (dependent upon the size of the object),

Strains from 100 microstrain to 2000% and above are possible with down to 50 microstrain resolution.

Simple system setup, requires a quick calibration procedure and an applied random speckle pattern.

No special illumination or lasers required and there is no contact with the specimen during testing.

Pattern Preparation Area:

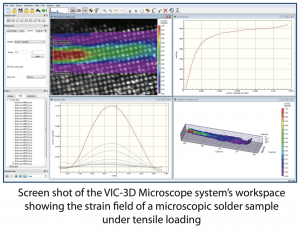

- Field of view (zoom range): 0.8mm-7mm

- Full-field measurements of 3D coordinates, displacements, velocities, and complete strain tensors

- Automatic calibration

- Image pairs can be automatically overlapped with a simple adjustment

- Powerful tools for visualizing data

- Contour displays which can be overlaid onto images of the test specimen

- Data extraction from 3D plots based on user defined lines and circles

- Post-processing tools for statistical analysis, stress-strain curves, and more

- Convenient exporting of data with the FLEXPortTM data tool

- Data can be exported in Tecplot/plain ASCII, Matlab, and STL formats

- Node data can be easily extracted for FEA validation

Max Frame Rate: 275,000 fps at 1024 x 8 pixels

Max Resolution: 1200 fps at 4096 x 2304 pixels

Pixel size: 10 µm x 10 µm

Sensor Size: 28.96 mm

Specification Telops FAST M100hd

Detector type InSb

Internal High-Speed Memory 16 GB

Spectral resolution 1280 × 1024 pixels

Pixel Pitch 10 μm

Spectral range 1.5 to 5.4 μm

Optical aperture F/3

Typical NETD 30 mK

Maximum frame rate @ 320×256 335 Hz

Maximum frame rate @ 1280 x 1024 100 Hz

Operational Environment -15°C to +50°C

Storage Environment -35°C to + 60°C

Calibration maximum 2500°C

Sample Preparation

The GIGA-1200 is designed to prepare even the most difficult to polish materials with a very gentle polishing action. Polishing is accomplished by setting the default frequency so that the sample begins to vibrate and then changing the voltage in order to adjust the rotational speed. The GIGA-1200 features an interchangeable polishing bowl and a variety of specimen holders and weight (quoted separately), FRP hood, heavy duty aluminum casting base, acrylic cover and durable plastic bowl.

Low/Medium Speed Precision Cutting Saw

• Internal coolant pump and Digital feedback speed control. Ideal for all materials and User friendly

• Variable wheel speeds from 50- 1500 rpm with digital feedback for constant speed control

• Accepts thin 3 (75 mm) to 7-inch 175 mm) wafering blade diameters •Capable of using 6 and 7-inch abrasive blades with 1/2-inch arbor (12.5 mm)

• Built-in digital micrometer